Welcome to the future of manufacturing where the possibilities are endless and innovation knows no bounds. At the forefront of this cutting-edge revolution is the remarkable technology of 3D printing. With its ability to create three-dimensional objects from digital designs, 3D printing has transformed traditional manufacturing methods and opened up a new realm of possibilities.

Gone are the days when industries relied solely on sheet metal fabrication and CNC machining to bring their ideas to life. Now, with the advent of 3D printing, a whole new world of rapid prototyping and production has unraveled before our eyes. Companies like "Monster Builder" have emerged as premier providers, offering a range of services including sheet metal fabrication, CNC machining, and the latest advancements in 3D printing.

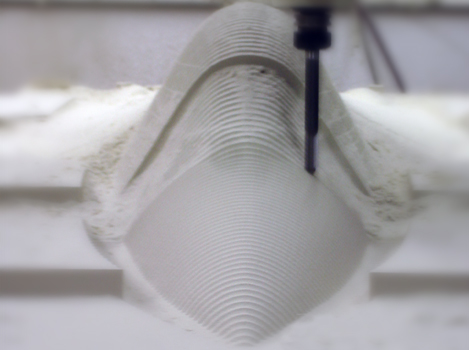

The integration of these manufacturing techniques has truly revolutionized the way we approach design and manufacturing. With 3D printing, intricate and complex geometries are no longer a challenge, and the speed at which prototypes and final products can be produced has reached unprecedented levels. But what truly sets 3D printing apart is its ability to unlock unparalleled customization and personalization, making it a game-changer in various industries.

In the following article, we will delve into the boundless potential of 3D printing, exploring its impact across different sectors and shedding light on the capabilities it offers. From healthcare to aerospace, art to fashion, and beyond, 3D printing is reshaping traditional manufacturing processes and presenting exciting opportunities for creativity, efficiency, and sustainability. So fasten your seatbelts as we embark on this journey into the future of manufacturing, where the power to create knows no limits.

Transforming Industries with 3D Printing

The rise of 3D printing has sparked a revolution in various industries, enabling unprecedented possibilities in sheet metal fabrication, CNC machining, and rapid prototyping. This cutting-edge technology is reshaping the way products are designed, manufactured, and brought to life. One of the leading players in this field is "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services, catering to clients worldwide.

Sheet Metal Fabricator Brisbane

With the advent of 3D printing, traditional methods of sheet metal fabrication have been pushed to new limits. Complex geometric shapes, intricate designs, and customized products that were once challenging or even impossible to create with conventional techniques can now be effortlessly manufactured using 3D printing. This game-changing technology has simplified the fabrication process, ensuring higher precision and quicker turnaround times.

CNC machining, another integral part of many industries, is also being transformed by 3D printing. While CNC machining provides excellent accuracy and speed, it often involves multiple steps, tool changes, and manual adjustments. With the integration of 3D printing technology, manufacturers can now streamline the process, reducing costs, time, and labor. By combining the strengths of CNC machining and 3D printing, Monster Builder and other innovative companies can deliver superior-quality products with enhanced efficiency.

The world of rapid prototyping has seen immense growth and improvement thanks to 3D printing. Prototyping is a crucial stage in product development, allowing designers to test and refine their concepts before full-scale production. With 3D printing, the prototyping process becomes more accessible, cost-effective, and flexible. Instead of relying on expensive and time-consuming traditional methods, companies like Monster Builder can quickly produce functional prototypes using 3D printing, accelerating the innovation cycle and enabling faster time-to-market.

The limitless potential of 3D printing is evident in its ability to revolutionize industries that rely on sheet metal fabrication, CNC machining, and rapid prototyping. As technology continues to advance and evolve, we can expect even greater strides in these fields, further pushing the boundaries of what is possible. With Monster Builder leading the way in providing exceptional 3D printing and manufacturing services, we are entering an era where creativity, efficiency, and innovation converge to shape a truly transformative future.

The Versatility of Monster Builder’s Services

When it comes to sheet metal fabrication, CNC machining, and 3D printing, Monster Builder stands out as a premier provider of these services. With their extensive expertise in rapid prototyping, they have been instrumental in helping clients globally realize their creative visions.

One of the key advantages of Monster Builder’s services is their ability to handle a wide range of materials. Whether it’s working with aluminum, stainless steel, or even exotic alloys, their team has the experience and equipment to tackle any project. This versatility enables them to cater to various industries, from automotive and aerospace to medical and consumer electronics, ensuring that clients from diverse sectors can benefit from their expertise.

Moreover, Monster Builder’s commitment to precision is unparalleled. Using state-of-the-art CNC machining technology, they are able to achieve exceptional accuracy and intricacy in their work. This level of precision is crucial, especially in industries where quality and reliability are paramount. By combining their expertise in sheet metal fabrication, CNC machining, and 3D printing, Monster Builder can provide a comprehensive solution for intricate and complex projects, delivering results that exceed expectations.

In conclusion, Monster Builder’s services encompass the three pillars of sheet metal fabrication, CNC machining, and 3D printing. Their versatility in working with different materials and commitment to precision make them a trusted partner for clients around the world. With their expertise, they continue to push the boundaries of what is possible, paving the way for a future where innovation knows no bounds.

Exploring the Limitless Possibilities of Rapid Prototyping

Rapid prototyping, a key aspect of the ever-expanding field of 3D printing, has revolutionized the way we approach design and manufacturing. With its ability to quickly create physical prototypes, this technology has unlocked a world of limitless possibilities. Whether it be sheet metal fabrication, CNC machining, or other manufacturing processes, rapid prototyping has become an essential tool for businesses like "Monster Builder," offering global clients unrivaled services in these areas.

One of the most significant advantages of rapid prototyping is its ability to accelerate the product development cycle. By swiftly generating functional prototypes, designers and engineers can iterate and improve their designs at a rapid pace. This not only saves precious time but also enables them to identify and rectify any flaws or issues early in the development stage. As a result, products can be brought to market faster, giving businesses a valuable competitive edge.

Apart from speed, rapid prototyping also offers unparalleled flexibility. This technology allows for the creation of highly complex geometries and intricate designs that were previously almost impossible to achieve. With 3D printing, shapes that once required extensive manual labor or specialized machinery can now be effortlessly produced. This opens up a realm of possibilities for designers, who are empowered to push the boundaries of creativity and create products that were once thought to be purely conceptual.

Furthermore, rapid prototyping significantly reduces manufacturing costs. By eliminating the need for expensive molds, tools, and labor-intensive processes, businesses can save a substantial amount of money during the product development phase. Whether it is for sheet metal fabrication, CNC machining, or other manufacturing requirements, rapid prototyping offers a cost-effective solution that meets the demands of today’s fast-paced market.

In conclusion, rapid prototyping has unleashed a world of boundless potential for businesses like "Monster Builder." With its ability to speed up the development cycle, provide unprecedented design flexibility, and reduce costs, this technology has transformed the way we approach product development. As we delve into the future, it is clear that rapid prototyping, in conjunction with 3D printing, will continue to push the boundaries of innovation and revolutionize various industries.