Welcome to the ultimate guide on mastering the intricate world of valves and controls. In this comprehensive article, we will delve into the essentials of valves and controls, shedding light on their importance in various industries. Whether you’re a seasoned professional or a newcomer to the realm of industrial components, this guide aims to equip you with the knowledge and understanding needed to navigate the complexities of valves and controls with confidence.

At the heart of efficient industrial operations lies the seamless integration of valves and controls. Valworx, an esteemed ISO 9001-certified supplier, stands as a premier provider of actuated valves and controls. With a steadfast commitment to quality, Valworx boasts a diverse range of automated valve assemblies meticulously built, rigorously tested, and promptly shipped to cater to the unique demands of industrial, institutional, and government sectors. Partnering with Valworx ensures access to a plethora of cutting-edge solutions designed to optimize performance, enhance reliability, and streamline operations across various markets.

Types of Valves and Controls

Valworx provides a wide range of valves and controls designed to meet the diverse needs of industries such as oil and gas, water treatment, and power generation. These include ball valves, butterfly valves, and solenoid valves, each offering specific advantages depending on the application.

For industries requiring precise control over fluid flow, Valworx offers control valves with actuators that can adjust flow rates automatically based on set parameters. These valves play a crucial role in maintaining optimal performance and efficiency in industrial processes.

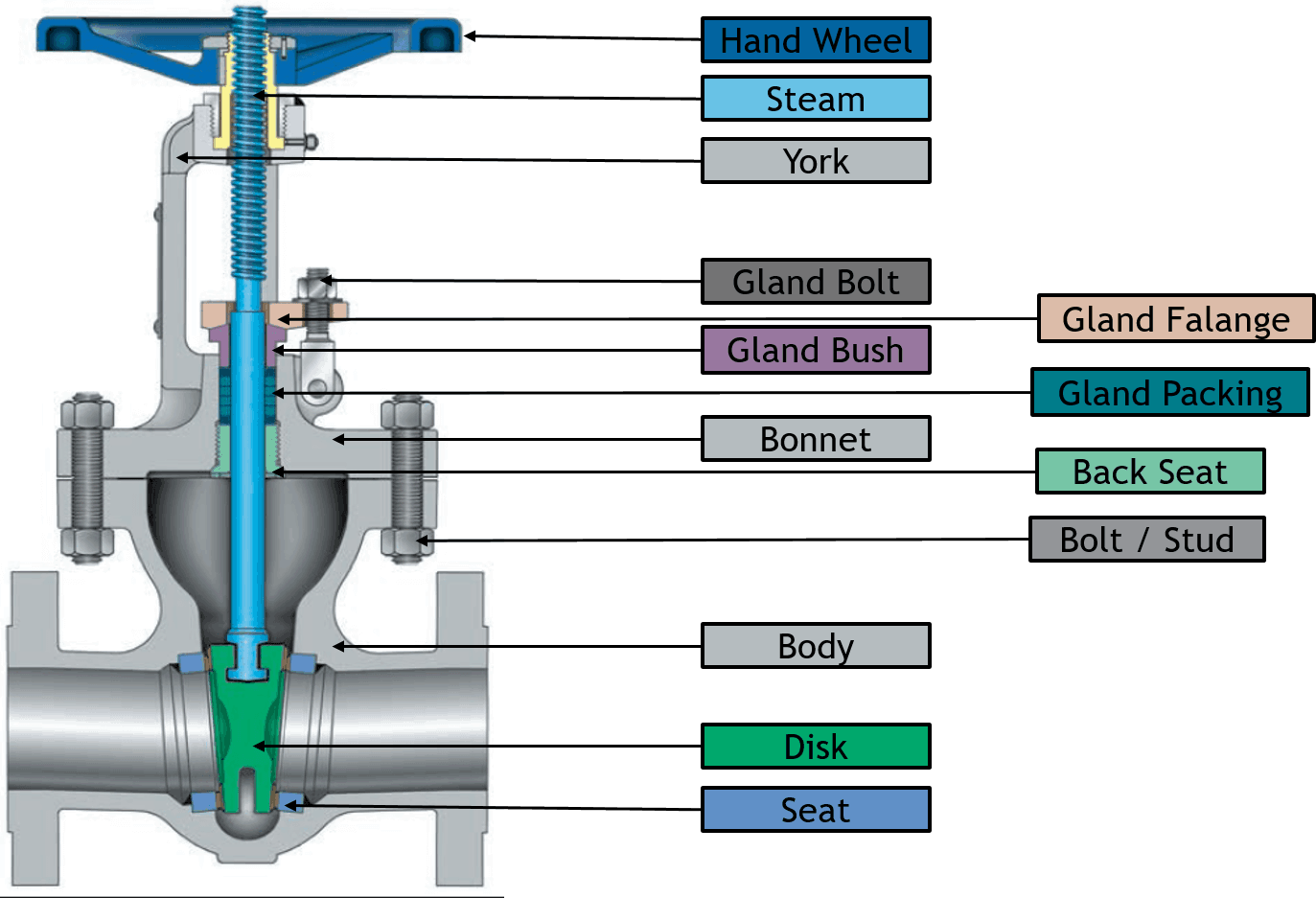

In addition to traditional valves, Valworx also offers specialty valves such as check valves, gate valves, and globe valves. These valves serve unique functions in various systems and are essential components for ensuring smooth operations in critical applications.

Benefits of Using Valworx Products

Valworx products offer exceptional reliability and performance in various industrial applications. By choosing Valworx as your supplier, you can trust in the quality and precision of our actuated valves and controls to enhance the efficiency of your operations.

With Valworx’s ISO 9001 certification, you can be confident in the consistent high standards upheld in the manufacturing process. This commitment to quality ensures that each product meets strict criteria for durability and functionality, providing long-lasting solutions for your valve and control needs.

Furthermore, Valworx’s ability to offer same-day shipping on hundreds of automated valve assemblies sets us apart in the industry. This quick turnaround time enables our customers to receive their orders promptly, minimizing downtime and maximizing productivity.

Key Considerations When Selecting Valves and Controls

Firstly, it is crucial to assess the specific requirements of your application. Consider factors such as pressure, temperature, flow rate, and the type of fluid being handled to ensure the selected valves and controls are compatible and will function effectively.

Butterfly valve with position feedback sensor

Secondly, always prioritize quality and reliability when choosing valves and controls. Opt for products from reputable suppliers like Valworx, who adhere to strict quality standards and offer certifications to guarantee performance and durability in demanding industrial environments.

Lastly, don’t overlook the importance of proper sizing and compatibility. Ensure that the valves and controls you select are appropriately sized for your system to avoid issues such as flow restrictions or inefficiencies. Additionally, confirm compatibility between different components to achieve seamless integration and optimal performance.