In the world of analytical chemistry, precision is not just a goal; it is a necessity. High-precision laboratory analytical balances play a vital role in ensuring that measurements are accurate and reliable. These instruments serve as the backbone of countless experiments, providing the critical data that researchers rely on to make informed decisions. Whether in pharmaceuticals, food safety, or environmental testing, the accuracy of these balances directly impacts the integrity of the results.

W&J Instrument stands out as a professional manufacturer and seller of a wide variety of electronic balances, moisture analyzers, viscometers, and other laboratory instruments. Their commitment to quality and precision ensures that laboratories around the globe can maintain the accuracy required for their analytical tasks. As we delve into the Calibration Chronicles, we will explore the significance of proper calibration and maintenance of these sophisticated instruments to guarantee their performance and reliability in any analytical setting.

Importance of Calibration

Analytical Balance Calibration Services

Calibration is a critical aspect of maintaining the accuracy and reliability of analytical lab balances. These balances are essential for precise measurements in various scientific fields, including pharmaceuticals, chemistry, and food science. Accurate measurements ensure that experiments yield valid results, which can influence research outcomes, product quality, and compliance with regulatory standards. Without proper calibration, the risk of errors increases significantly, potentially compromising the integrity of analytical work.

Regular calibration helps to identify deviations in balance performance and compensates for these discrepancies. Factors such as temperature fluctuations, environmental conditions, and regular wear and tear can affect the accuracy of lab balances. By establishing a routine calibration schedule, laboratories can minimize these impacts and maintain optimal performance. This proactive approach not only fortifies the reliability of results but also enhances the overall efficiency of laboratory operations.

Furthermore, adherence to calibration standards is essential for accreditation and certification purposes. Various regulatory bodies require that laboratory instruments, including analytical balances, meet specific accuracy standards. Non-compliance may lead to revoked certifications, affecting a laboratory’s reputation and its ability to operate effectively. By prioritizing calibration, laboratories align themselves with industry best practices and uphold the quality and trustworthiness of their analytical processes.

Types of Lab Balances

Laboratory balances are essential tools for precise measurement in various scientific applications. There are several types of laboratory balances, each designed to serve specific needs based on sensitivity and capacity. Top-loading balances are commonly used for general weighing tasks. They offer a versatile range of capacities and are user-friendly, making them ideal for routine laboratory work. Their ease of use allows for a quick setup, which is vital in high-throughput environments.

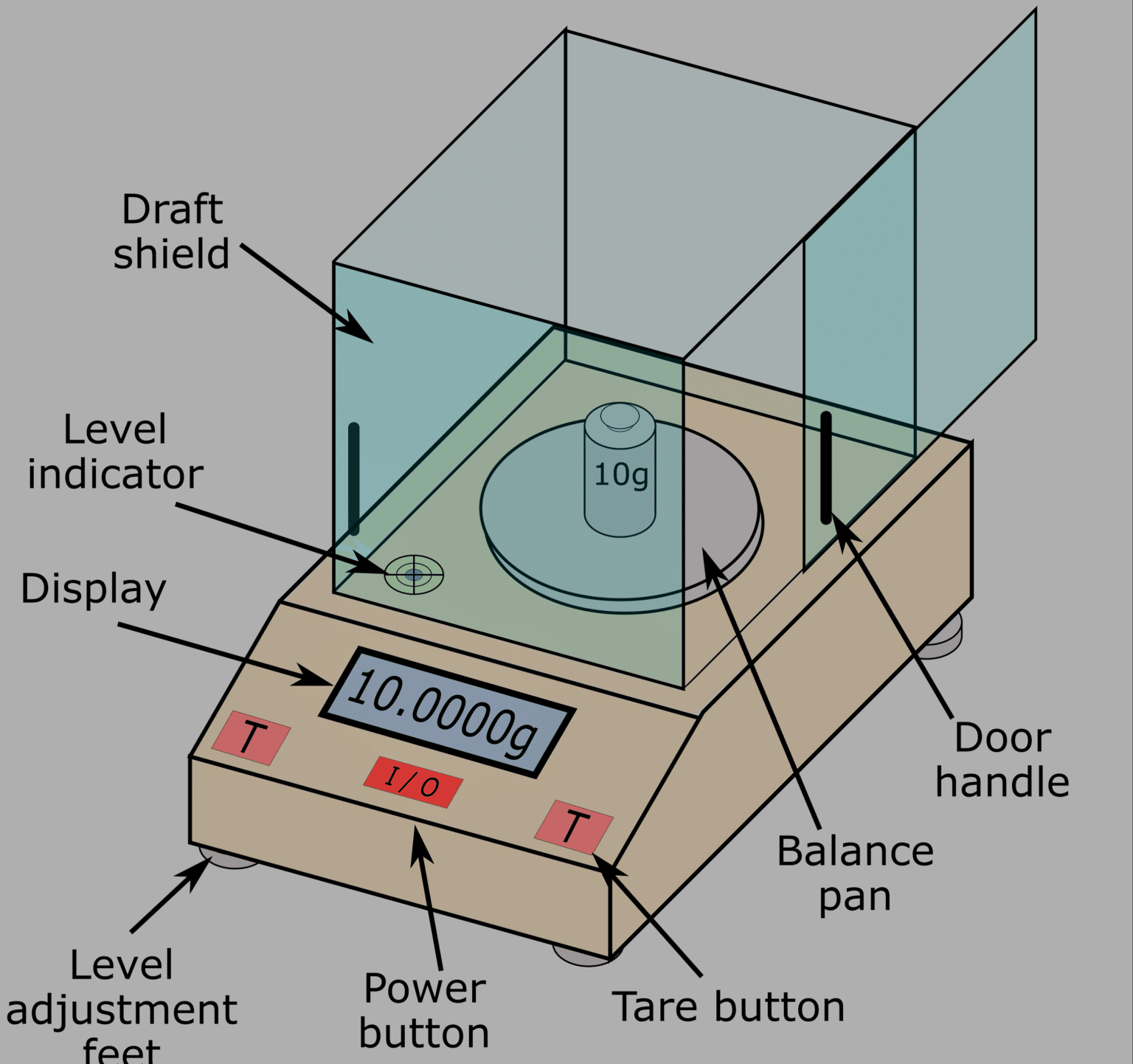

Analytical balances represent a higher tier of precision, typically used for weighing samples to an accuracy of 0.0001 grams or better. These balances are equipped with draft shields to protect sensitive samples from environmental disturbances such as air currents and vibrations. Due to their high resolution, analytical balances are crucial in applications that require meticulous measurements, such as pharmaceutical research or chemical formulation.

Microbalances take precision to an even greater level, measuring masses in the microgram range. These extremely sensitive devices are used in specialized laboratories where minimal sample sizes are standard, such as in the study of fine powders or delicate materials. Utilizing advanced technology, microbalances can detect minute weight changes, providing researchers with the exact measurements they need for their intricate experiments.

Calibration Procedures

Calibration of high-precision laboratory analytical balances is essential for ensuring measurement accuracy and reliability. The process typically begins with a thorough inspection of the balance to ensure it is clean and free from any obstructions that could affect weight measurements. Regularly cleaning the balance with appropriate solutions prevents contamination and maintains the integrity of data.

Next, a series of standardized weights is used to verify the balance’s accuracy. It is crucial to select calibration weights that are traceable to national or international standards to ensure reliability. Depending on the specific requirements of the lab, calibrations should be conducted at various points across the balance’s operating range. This process not only identifies any systematic errors but also helps in adjusting the balance settings to conform to precise measurement standards.

Finally, after the calibration is completed, it is important to document the results comprehensively. Each calibration should be recorded with specific details, including the date, environmental conditions, and any adjustments made. Keeping an accurate log allows for continued monitoring of the equipment’s performance over time, enabling laboratories to maintain high standards of accuracy and reliability in their analytical processes. Regular calibration intervals, as suggested by manufacturers like W&J Instrument, help ensure ongoing precision in laboratory measurements.

W&J Instrument’s Solutions

W&J Instrument stands out in the industry with a comprehensive range of high-precision laboratory analytical balances designed to meet the rigorous standards of research and quality control. Their balances are equipped with advanced technology that ensures exceptional accuracy and repeatability, making them essential tools for laboratories where precise measurements are critical. By integrating features such as automatic calibration and multiple weighing modes, W&J Instrument offers versatility suited for diverse applications.

In addition to analytical balances, W&J Instrument also provides moisture analyzers and viscometers, enabling laboratories to tackle a variety of analytical challenges. The moisture analyzers are particularly useful for determining the water content in samples, a crucial factor in quality assessment for many industries. Meanwhile, viscometers allow researchers to measure the viscosity of fluids, making them indispensable in fields ranging from food science to pharmaceuticals. Together, these instruments create a cohesive system for maintaining accuracy in lab measurements.

W&J Instrument is committed to customer satisfaction, offering not just cutting-edge equipment but also exceptional support and service. Their team of experts is dedicated to helping laboratories optimize their measurement processes, providing training and troubleshooting assistance as needed. With W&J Instrument’s solutions, laboratories can trust that they are equipped with the most reliable tools to ensure precision in their analytical work.